Who are we?

A little history...

This is the story of a personalized key ring brought back from the States in the spring of 2010 by a globetrotter. A key ring made from the conventional Dog Tag military dog tags worn around the neck by soldiers in the US Army. The same dog tags that punctuated the American cinema of an entire era. Rambo, Top Gun, Full Metal Jacket, Platoon, Apocalypse Now come to mind... Popularized by Hollywood, then largely diverted from its original use as costume jewelry, the Dog Tag is now pursuing a form of demilitarization in the "civilian" world. And it is under its new name, ID Tag, that it will continue to evolve. From 2014 onwards, it will even be seen on the catwalks, where it will become one of the hallmarks of a clothing trend: military fashion. A trend that, from 2017 onwards, will continue to evolve towards a camouflage (or camo) style, now identity-oriented. But back to MonIDTag...

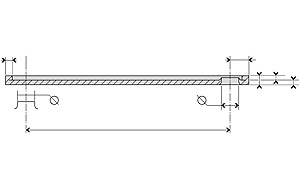

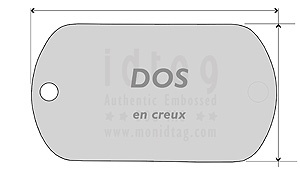

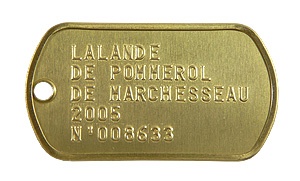

After a few months of incubation, the first dog tag came out of the embosser on December 22, 2010. During this time, the "ordinary" story of a business project unfolds, with its ups and downs, its stress, its joys and its results. A project called MON ID TAG, pronounced MON IDÉE TAG [sorry for the barbaric phonetics :-D ] or MON AÏE DI TAG. A first website was launched around February 2011, specializing in the embossed engraving of steel Dog Tags. Along the way, MonIDTag doubled its production capacity in 2013 and gradually expanded its manufacturing to other materials such as brass, copper, aluminum or even silver but always around the dog tag format, i.e. an oblong 5 x 2.8 cm.

In 2014, MonIDTag integrated a mechanical engraver then in 2016, a laser engraver. In the meantime, MonIDTag specializes in cutting and polishing cutting and polishing of 950 silver military plates.. In 2020, the MonIDTag business was sold to Sarl STUDIO GLYPHE.

MonIDTag today...

In 2021, after 10 years in business, the website gets a facelift. Fully responsive, it enables visitors to compose a dog tag from from A to Z using an advanced dialerin discovery mode. And for regular visitors, they can use pre-composed pre-composed suggestions ready to personalize.

Diversification projects are underway, including the engraving of FIRM PLATES and IDENTIFICATION PLATES in METAL (tank identification, industrial machine identification, identification of mechanical assemblies, etc.). MonIDTag also plans to launch a complete range of animal identification tags. What's more, with a maximum production capacity of 500 embossed and 400 laser-engraved military tags per day, the workshop is able to respond to the single-unit needs that remain its core business, as well as to ultra-customized medium-sized production runs. That's between 2,000 and 2,500 UNIT engravings per week, depending on the process chosen. In this way, MonIDTag is able to meet certain requirements linked to sporting events (finisher medals, for example) as well as marketing events, sales operations, etc...